Einführung in die Extraktion ätherischer Öle

Natur der ätherischen Öle in Pflanzen

Ätherische Öle sind ein bemerkenswertes biochemisches Produkt von Pflanzen, das aufgrund ihrer einzigartigen physiologischen und biochemischen Eigenschaften synthetisiert wird. Diese Öle sind nicht gleichmäßig in der Pflanze verteilt, sondern konzentrieren sich in bestimmten Teilen wie Epidermiszellen, Drüsenhaaren und spezialisierten Strukturen wie Harzkanälen und sekretorischen Hohlräumen. Das Vorhandensein dieser Öle in solchen lokal begrenzten Bereichen erfüllt mehrere Funktionen, darunter die Abwehr von Pflanzenfressern, das Anlocken von Bestäubern und den Schutz vor Umweltbelastungen.

Die Produktion ätherischer Öle ist ein komplexer Prozess, an dem eine Reihe von biochemischen Prozessen beteiligt sind. Diese Wege werden häufig durch Umweltfaktoren wie Licht, Temperatur und Bodenzusammensetzung sowie durch genetische Faktoren reguliert. Die daraus resultierenden Öle sind in ihrer chemischen Zusammensetzung sehr unterschiedlich, wobei jede Pflanzenart typischerweise eine einzigartige Mischung aus Terpenen, Phenolen, Estern und anderen Verbindungen produziert. Diese Vielfalt ist ausschlaggebend für die ökologische Funktion dieser Öle und bildet auch die Grundlage für ihre vielfältigen Anwendungen beim Menschen, von der Aromatherapie bis zur medizinischen Behandlung.

Neben ihrer funktionellen Rolle innerhalb der Pflanze unterstreichen die einzigartigen Speicherorte der ätherischen Öle, wie z. B. in Drüsentrichomen auf den Blättern oder in den sekretorischen Hohlräumen der Blüten, die spezielle Natur dieser Verbindungen. Diese Speichermechanismen schützen die Öle nicht nur vor dem Abbau, sondern erleichtern auch ihre Freisetzung im Bedarfsfall, sei es zur Anlockung nützlicher Insekten oder zur Abwehr von Schädlingen. Das Verständnis der Natur und der Verteilung der ätherischen Öle in den Pflanzen ist daher der Schlüssel zur Optimierung ihrer Extraktionsverfahren und zur Maximierung ihres potenziellen Nutzens.

Herausforderungen bei den Extraktionsmethoden

Herkömmliche Extraktionsverfahren wie die Destillation stellen eine große Herausforderung dar, um die Integrität der ätherischen Öle zu erhalten. Bei diesen Verfahren werden häufig hohe Temperaturen und Verdampfungsprozesse eingesetzt, die zu einer Veränderung der chemischen Zusammensetzung der Öle führen können. Diese Veränderung kann zum Abbau wertvoller Verbindungen führen und die Gesamteffizienz und -effektivität des Extraktionsprozesses verringern.

Beispielsweise kann die bei der Destillation angewandte Hitze zu einer thermischen Zersetzung bestimmter empfindlicher Verbindungen führen, was einen Verlust ihrer therapeutischen Eigenschaften zur Folge hat. Darüber hinaus kann der Verdampfungsprozess zum Verlust von flüchtigen Ölen führen, die für das gewünschte Aroma und die medizinische Wirkung entscheidend sind. Diese Nachteile verdeutlichen den Bedarf an fortschrittlicheren und präziseren Extraktionsverfahren, mit denen die natürliche Zusammensetzung und Wirksamkeit der ätherischen Öle erhalten werden kann.

Um diesen Herausforderungen zu begegnen, wurden moderne Extraktionstechnologien wie die überkritische CO2-Extraktion, die supramolekulare Extraktion und die gezielte Extraktion entwickelt. Diese Methoden bieten kontrolliertere Umgebungen und selektive Extraktionsmöglichkeiten, wodurch das Risiko chemischer Veränderungen und des Verlusts wertvoller Verbindungen minimiert wird.

Modernste Extraktionstechnologien

Überkritische CO2-Extraktion

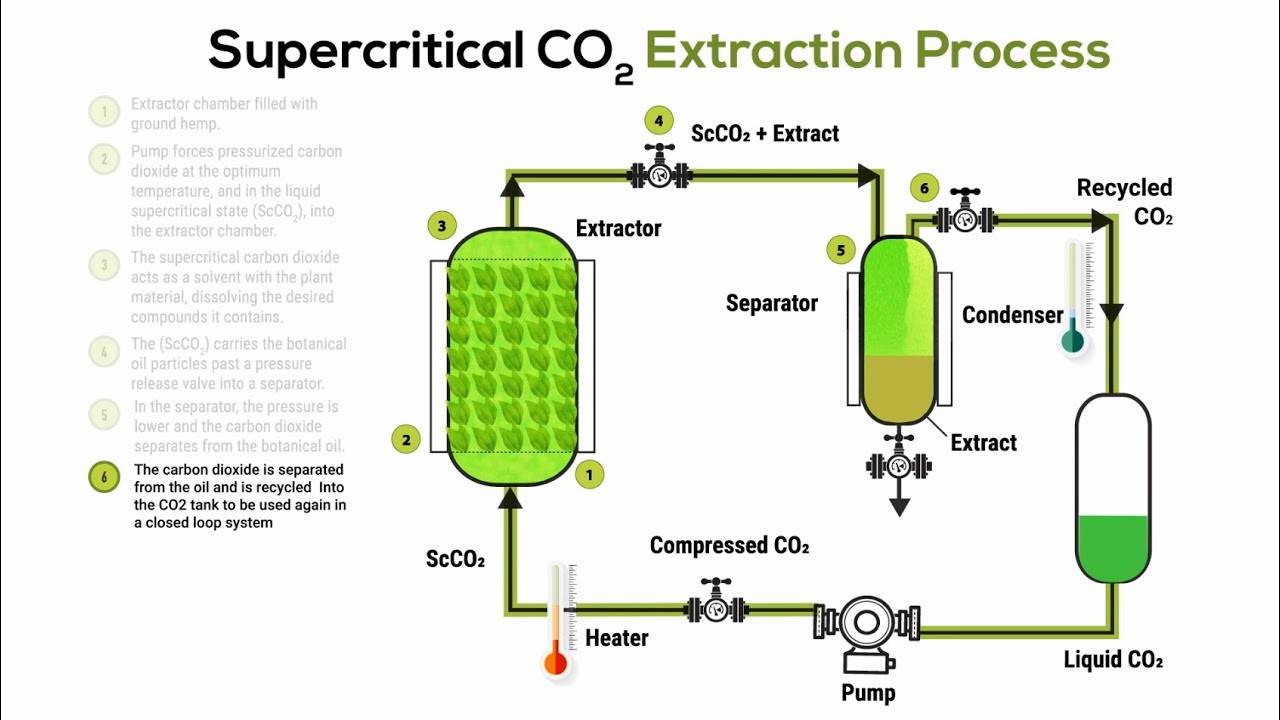

Die superkritische CO2-Extraktion nutzt die Vorteile der superkritischen Flüssigkeitstechnologie, bei der Kohlendioxid (CO2) als Lösungsmittel verwendet wird. Bei dieser Methode wird CO2 unter Druck gesetzt, um einen überkritischen Zustand zu erreichen, in dem es sowohl die Eigenschaften eines Gases als auch die einer Flüssigkeit aufweist. Der CO2-Strom wird dann durch eine Kammer geleitet, die das Cannabismaterial enthält, wodurch die Wirkstoffe effektiv extrahiert werden.

Einer der Hauptvorteile dieser Technik ist ihre Einfachheit und die niedrigen Betriebstemperaturen, die dazu beitragen, die Integrität der extrahierten Verbindungen zu erhalten. Das Verfahren ist jedoch nicht ohne Nachteile. Die anfänglichen Einrichtungs- und Betriebskosten sind hoch, und die Methode ist in erster Linie für unpolare Moleküle geeignet.

Um die Extraktion zu optimieren, können Temperatur und Druck fein abgestimmt werden, so dass ein vollständiges Terpenprofil erhalten bleibt. Fortgeschrittene Systeme können eine Fraktionierung beinhalten, die die Isolierung spezifischer Komponenten ermöglicht. Darüber hinaus werden Kühlgeräte und Umlauferhitzer integriert, um das Recycling von CO2 zu erleichtern und einen effizienten und kontrollierten Betrieb zu gewährleisten.

| Vorteile | Nachteile |

|---|---|

| Einfacher Prozess | Hohe Kosten |

| Niedrige Betriebstemperatur | Begrenzt auf unpolare Moleküle |

| Bewahrt das Terpenprofil | Erfordert anspruchsvolle Ausrüstung |

| Effizientes CO2-Recycling |

Zusammenfassend lässt sich sagen, dass die überkritische CO2-Extraktion zwar erhebliche Vorteile in Bezug auf die Einfachheit des Prozesses und die Erhaltung der Verbindungen bietet, aber durch ihre hohen Kosten und ihre begrenzte Anwendbarkeit auf unpolare Moleküle eingeschränkt ist. Nichtsdestotrotz macht ihre Fähigkeit, qualitativ hochwertige Extrakte zu gewinnen, sie zu einem wertvollen Werkzeug auf dem Gebiet der Pflanzenextraktionswissenschaft.

Supramolekulare Extraktion

Die supramolekulare Extraktion ist eine hochentwickelte Methode, die die Kraft supramolekularer Systeme zur selektiven Isolierung von Zielsubstanzen nutzt. Diese Technik zeichnet sich durch ihre Schnelligkeit und Effizienz aus, was sie zu einer vielversprechenden Alternative auf dem Gebiet der Extraktion von Aromapflanzen macht. Im Gegensatz zu den herkömmlichen Methoden, bei denen oft hohe Temperaturen und potenziell schädliche Lösungsmittel zum Einsatz kommen, arbeitet die supramolekulare Extraktion unter milderen Bedingungen, wodurch die Integrität der extrahierten Verbindungen erhalten bleibt.

Die Umweltfreundlichkeit der supramolekularen Extraktion ist ein weiteres bemerkenswertes Merkmal. Durch die Minimierung des Einsatzes aggressiver Chemikalien und die Verringerung des Abfallaufkommens steht diese Methode im Einklang mit modernen Nachhaltigkeitszielen. Trotz dieser Vorteile wird die supramolekulare Extraktion in der Aromapflanzenextraktion noch relativ selten angewandt, was vor allem auf die Komplexität und die Kosten zurückzuführen ist, die mit dem Aufbau der erforderlichen supramolekularen Systeme verbunden sind.

Zusammenfassend lässt sich sagen, dass die supramolekulare Extraktion zwar einen schnellen, effizienten und umweltfreundlichen Ansatz zur Isolierung von Substanzen bietet, ihre breitere Anwendung im Bereich der Extraktion aromatischer Pflanzen jedoch noch in den Kinderschuhen steckt. Zukünftige Forschungs- und Entwicklungsarbeiten könnten diese Lücke möglicherweise schließen und diese fortschrittliche Technik in der Industrie zugänglicher und verbreiteter machen.

Gezielte Extraktion

Die gezielte Extraktion ist ein hochentwickelter Ansatz zur Isolierung spezifischer Wirkstoffe aus Pflanzenmaterialien, der auf fortschrittlichen Techniken zur Zielmodellierung beruht. Diese Methode ist von entscheidender Bedeutung für die Einhaltung der strengen Anforderungen der neuen kosmetischen Vorschriften und gewährleistet, dass die Produkte den höchsten Sicherheits- und Wirksamkeitsstandards entsprechen. Trotz ihrer bedeutenden Vorteile ist die gezielte Extraktion nach wie vor ein kostspieliges Unterfangen, das aufgrund der hohen Präzision und der erforderlichen Spezialausrüstung in erster Linie auf den Pharmasektor beschränkt ist.

Bei der Herstellung von Kosmetika ist die Fähigkeit zur präzisen Extraktion und Quantifizierung von Wirkstoffen von entscheidender Bedeutung. Neue gesetzliche Rahmenbedingungen verlangen nicht nur das Vorhandensein wirksamer Bestandteile, sondern auch deren genaue Messung und Dokumentation. Die gezielte Extraktion zeichnet sich in dieser Hinsicht aus, denn sie bietet eine Lösung, mit der die gewünschten Verbindungen präzise identifiziert und isoliert werden können, was die Einhaltung dieser strengen Normen erleichtert.

Die finanziellen und technischen Hürden, die mit der gezielten Extraktion verbunden sind, schränken jedoch ihre breite Anwendung außerhalb der Pharmaindustrie ein. Das Verfahren erfordert modernste Technologie und hochqualifiziertes Personal, was beides zu seiner hohen Kostenstruktur beiträgt. Obwohl die Kosmetikindustrie das Potenzial dieser Methode erkannt hat, bleibt ihre Anwendung daher beschränkt, da sie auf Fortschritte wartet, die ihre Anwendung demokratisieren und für breitere Sektoren zugänglich machen könnten.

Moderne Extraktionstechniken, wie die Kurzweg-Destillation setzen sich aufgrund ihrer Effizienz und Präzision immer mehr durch. Außerdem werden Geräte wie der Wasserkühlungs-Umwälzpumpe eine entscheidende Rolle bei der Aufrechterhaltung optimaler Temperaturen während der Extraktionsprozesse, um die Erhaltung empfindlicher Verbindungen zu gewährleisten.

Ähnliche Produkte

- Labor-Prübsiebe und Siebmaschinen

- Labor-Autoklav Vertikaler Dampfsterilisator für Flüssigkristallanzeigen Automatischer Typ

- HFCVD-Maschinensystemausrüstung für Ziehstein-Nanodiamantbeschichtung

- Labor-Sterilisator Lab-Autoklav Puls-Vakuum-Hub-Sterilisator

- 915MHz MPCVD Diamantmaschine Mikrowellen-Plasma-Chemische Gasphasenabscheidung Systemreaktor

Ähnliche Artikel

- Inkonsistente Schmelzen? Das Problem ist nicht Ihr Ofen, sondern die Physik.

- Verständnis des heißisostatischen Pressens in PVD-Sputtertargets

- Die Physik der Perfektion: Warum Heißpressen eine Investition in Materialsicherheit ist

- Anwendung von Flüssigstickstoff beim Einfrieren von Lebensmitteln

- Arten von PECVD-Verfahren, Anlagenstruktur und Verfahrensprinzip