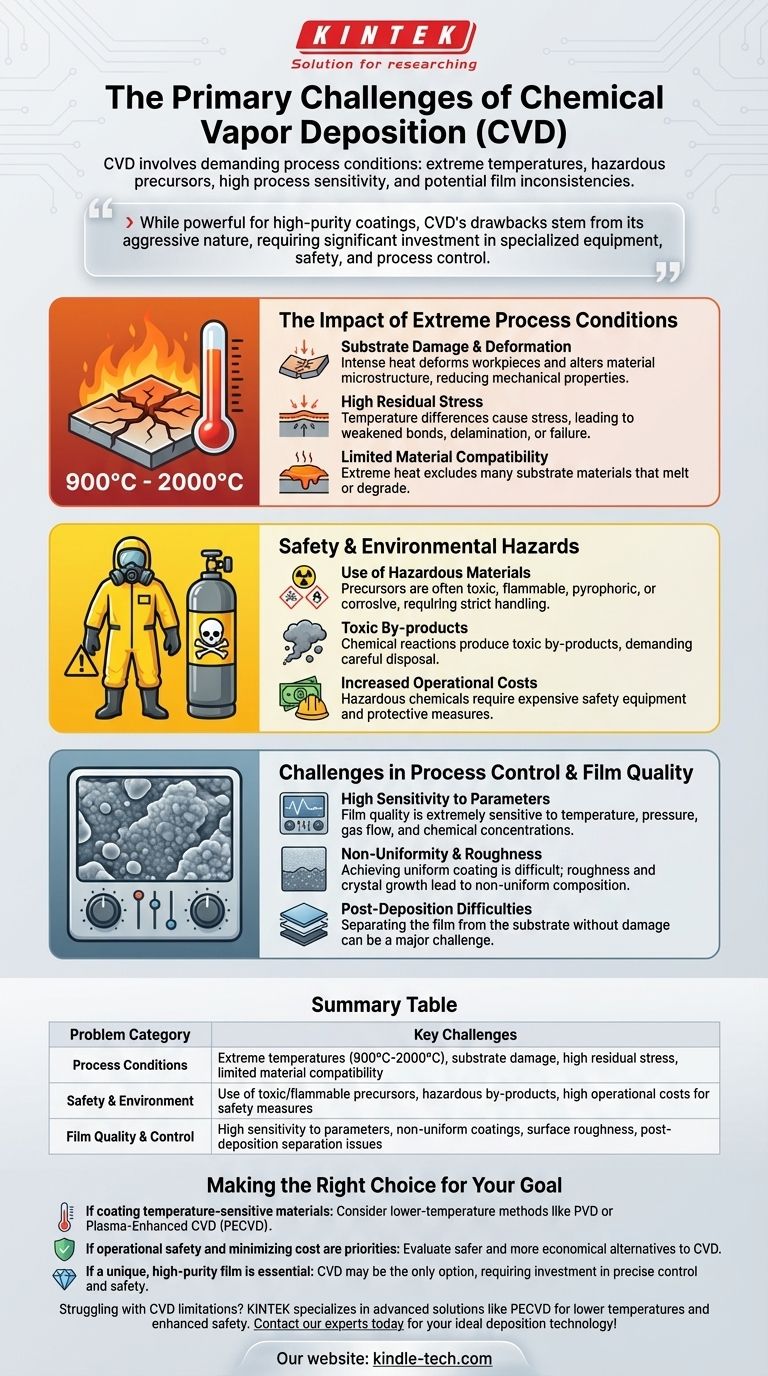

Die größten Herausforderungen der chemischen Gasphasenabscheidung (CVD) liegen in ihren anspruchsvollen Prozessbedingungen. Zu den Hauptproblemen gehören die Notwendigkeit extrem hoher Temperaturen, die Verwendung toxischer oder brennbarer Vorläufermaterialien, eine erhebliche Prozessempfindlichkeit und potenzielle Inkonsistenzen in der endgültigen Filmqualität. Diese Faktoren schaffen erhebliche Sicherheits-, Materialkompatibilitäts- und betriebliche Hürden.

Obwohl es sich um eine außergewöhnlich leistungsstarke Technik zur Herstellung hochreiner, hochleistungsfähiger Beschichtungen handelt, ergeben sich die grundlegenden Nachteile der CVD aus ihrer aggressiven chemischen Natur. Dies erfordert erhebliche Investitionen in spezielle Ausrüstung, Sicherheitsprotokolle und Prozesskontrolle, um Risiken sowohl für das Substrat als auch für den Bediener zu mindern.

Die Auswirkungen extremer Prozessbedingungen

Die bedeutendsten Einschränkungen der CVD ergeben sich oft aus ihrer Abhängigkeit von hohen Temperaturen, die von 900 °C bis 2000 °C reichen können. Diese thermische Energie ist notwendig, um die chemischen Reaktionen anzutreiben, führt aber auch zu mehreren Problemen.

Substratbeschädigung und -verformung

Solche intensive Hitze kann das zu beschichtende Werkstück oder Substrat leicht verformen.

Diese Hochtemperaturexposition kann auch die Mikrostruktur des Substratmaterials verändern und möglicherweise dessen mechanische Eigenschaften und die Gesamtintegrität reduzieren.

Hohe Eigenspannung

Der signifikante Temperaturunterschied zwischen dem Abscheidungsprozess und der Raumtemperatur kann zu hohen Eigenspannungen innerhalb der Beschichtung und an der Grenzfläche zum Substrat führen.

Diese Spannung kann die Bindung zwischen der Beschichtung und dem Substrat schwächen und manchmal zu Delamination oder Versagen führen.

Begrenzte Materialkompatibilität

Die extreme Hitze schränkt die Arten von Materialien, die als Substrate verwendet werden können, stark ein.

Viele Materialien können den erforderlichen Temperaturen nicht standhalten, ohne zu schmelzen, sich zu verformen oder zu degradieren, was CVD für eine Vielzahl von Anwendungen ungeeignet macht.

Sicherheits- und Umweltrisiken

CVD basiert auf flüchtigen Vorläuferchemikalien, um das Abscheidungsmaterial zu liefern. Die Natur dieser Chemikalien ist eine große Besorgnisquelle.

Verwendung gefährlicher Materialien

Viele der in CVD verwendeten Ausgangsmaterialien (Vorläufer) und reaktiven Gase sind hochgiftig, brennbar, pyrophor oder korrosiv.

Dies erfordert eine sorgfältige Materialhandhabung, Lagerung und ein robustes Systemdesign, um Lecks zu verhindern und die Sicherheit des Bedieners zu gewährleisten, was bei Prozessen wie der physikalischen Gasphasenabscheidung (PVD) weniger Anlass zur Sorge gibt.

Toxische Nebenprodukte

Die chemischen Reaktionen, die während der Abscheidung stattfinden, erzeugen oft toxische Nebenprodukte. Diese müssen sorgfältig gehandhabt und entsorgt werden, was den Prozess weniger umweltfreundlich macht als einige Alternativen.

Erhöhte Betriebskosten

Die gefährliche Natur der Chemikalien erfordert zusätzliche Investitionen in Sicherheit und Schutzausrüstung. Dies, kombiniert mit den hohen Kosten der CVD-Ausrüstung selbst, kann den Prozess teuer in der Implementierung und im sicheren Betrieb machen.

Herausforderungen bei der Prozesskontrolle und Filmqualität

Die Erzielung einer perfekten, gleichmäßigen Beschichtung mit CVD erfordert eine präzise Steuerung eines komplexen Zusammenspiels von Faktoren.

Hohe Empfindlichkeit gegenüber Parametern

Die Qualität des Endfilms ist extrem empfindlich gegenüber Prozessparametern wie Temperatur, Druck, Gasflussraten und chemischen Konzentrationen.

Wenn einer dieser Faktoren nicht mit hoher Präzision gesteuert wird, kann dies zu einem Film von schlechter Qualität oder sogar zu einem vollständigen Versagen des Abscheidungsprozesses führen.

Ungleichmäßigkeit und Rauheit

Es kann schwierig sein, einen perfekt gleichmäßigen Film über ein großes Substrat abzuscheiden, insbesondere bei komplexen Materialien wie Graphen.

Darüber hinaus weist die Oberfläche einer CVD-Beschichtung oft eine Rauheit auf, die sich mit der Filmdicke entwickelt, und ihre Kornstruktur kann aufgrund des Kristallwachstumsprozesses eine ungleichmäßige Zusammensetzung aufweisen.

Schwierigkeiten nach der Abscheidung

Für einige Anwendungen, wie die Herstellung freistehender Graphenschichten, ist das Abtrennen des abgeschiedenen Films vom Katalysatorsubstrat ohne Beschädigung oder Einführung von Verunreinigungen eine erhebliche technische Herausforderung.

Die richtige Wahl für Ihr Ziel treffen

Letztendlich hängt die Entscheidung für die Verwendung von CVD davon ab, ob ihre leistungsstarken Fähigkeiten gegen ihre erheblichen Nachteile abgewogen werden.

- Wenn Ihr Hauptaugenmerk auf der Beschichtung temperaturempfindlicher Materialien liegt: Standard-Hochtemperatur-CVD ist ungeeignet, und Sie sollten niedrigere Temperaturmethoden wie PVD oder Plasma-Enhanced CVD (PECVD) bevorzugen.

- Wenn Ihr Hauptaugenmerk auf der Betriebssicherheit und der Minimierung der Kosten liegt: Die gefährlichen Materialien und die spezielle Ausrüstung, die für CVD erforderlich sind, erfordern eine sorgfältige Abwägung von Alternativen, die einen sichereren und wirtschaftlicheren Prozess bieten könnten.

- Wenn Ihr Hauptaugenmerk auf der Erstellung eines einzigartigen, hochreinen Films liegt, der dies erfordert: CVD ist möglicherweise die einzig praktikable Option, aber der Erfolg erfordert erhebliche Investitionen in präzise Prozesskontrolle und strenge Sicherheitsprotokolle.

Das Verständnis dieser inhärenten Einschränkungen ist der erste Schritt zur Auswahl der richtigen Abscheidungstechnologie für Ihre spezifische Anwendung.

Zusammenfassungstabelle:

| Problemkategorie | Wichtige Herausforderungen |

|---|---|

| Prozessbedingungen | Extreme Temperaturen (900°C-2000°C), Substratbeschädigung, hohe Eigenspannung, begrenzte Materialkompatibilität |

| Sicherheit & Umwelt | Verwendung toxischer/brennbarer Vorläufer, gefährliche Nebenprodukte, hohe Betriebskosten für Sicherheitsmaßnahmen |

| Filmqualität & -kontrolle | Hohe Empfindlichkeit gegenüber Parametern, ungleichmäßige Beschichtungen, Oberflächenrauheit, Probleme bei der Trennung nach der Abscheidung |

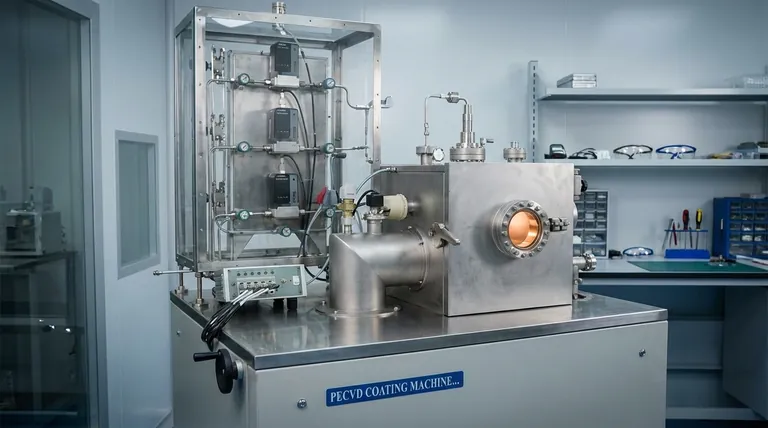

Haben Sie Schwierigkeiten mit CVD-Einschränkungen für die Beschichtungsanforderungen Ihres Labors? KINTEK ist auf Laborgeräte und Verbrauchsmaterialien spezialisiert und bietet fortschrittliche Lösungen wie Plasma-Enhanced CVD (PECVD)-Systeme, die bei niedrigeren Temperaturen mit erhöhter Sicherheit arbeiten. Unsere Expertise hilft Ihnen, hochreine Filme ohne die typischen CVD-Nachteile zu erzielen. Kontaktieren Sie noch heute unsere Experten, um die ideale Abscheidungstechnologie für Ihre spezifische Anwendung zu finden!

Visuelle Anleitung

Ähnliche Produkte

- Schräges Plasma-unterstütztes chemisches Gasphasenabscheidungs-PECVD-Röhrenofen-Gerät

- Chemische Gasphasenabscheidung CVD-Anlagenkammer-Schiebe-PECVD-Rohröfen mit Flüssiggasifikator PECVD-Maschine

- RF PECVD System Hochfrequenz-Plasma-unterstützte chemische Gasphasenabscheidung RF PECVD

- Kundenspezifische vielseitige CVD-Rohröfen-Systemausrüstung für die chemische Gasphasenabscheidung

- Geteilter Kammer-CVD-Röhrenofen mit Vakuumpumpe, Anlage für chemische Gasphasenabscheidung

Andere fragen auch

- Was sind die Prozessfähigkeiten von ICPCVD-Systemen? Erreichen Sie schädigungsarme Abscheidung von Filmen bei extrem niedrigen Temperaturen

- Was ist der Prozess der PECVD in der Halbleitertechnik? Ermöglichung der Niedertemperatur-Dünnschichtabscheidung

- Kann plasmaverstärkte CVD Metalle abscheiden? Warum PECVD selten zur Metallabscheidung verwendet wird

- Wie verbessern PECVD-Systeme DLC-Beschichtungen auf Implantaten? Überlegene Haltbarkeit und Biokompatibilität erklärt

- Warum benötigt ein PECVD-Vakuumsystem sowohl eine Drehschieber- als auch eine Turbopumpe? Gewährleistung von Hochreinen Beschichtungen