Die richtige Laborausrüstung wird nicht nach ihren Merkmalen ausgewählt, sondern durch eine rigorose Analyse Ihrer spezifischen Anwendung, des erforderlichen Durchsatzes und der Gesamtkosten des Besitzes. Dieser Prozess geht über den reinen Anschaffungspreis hinaus, um die langfristigen finanziellen und betrieblichen Auswirkungen eines Instruments zu bewerten und sicherzustellen, dass es als strategischer Vermögenswert und nicht als kostspielige Belastung dient.

Die Auswahl von Laborgeräten ist im Grunde eine Übung im Risikomanagement. Das Ziel ist es, Ihre wissenschaftlichen oder Produktionsziele abzusichern, indem Sie ein Werkzeug auswählen, das die von Ihnen benötigten Ergebnisse zuverlässig und kosteneffizient liefert, sowohl heute als auch in Zukunft.

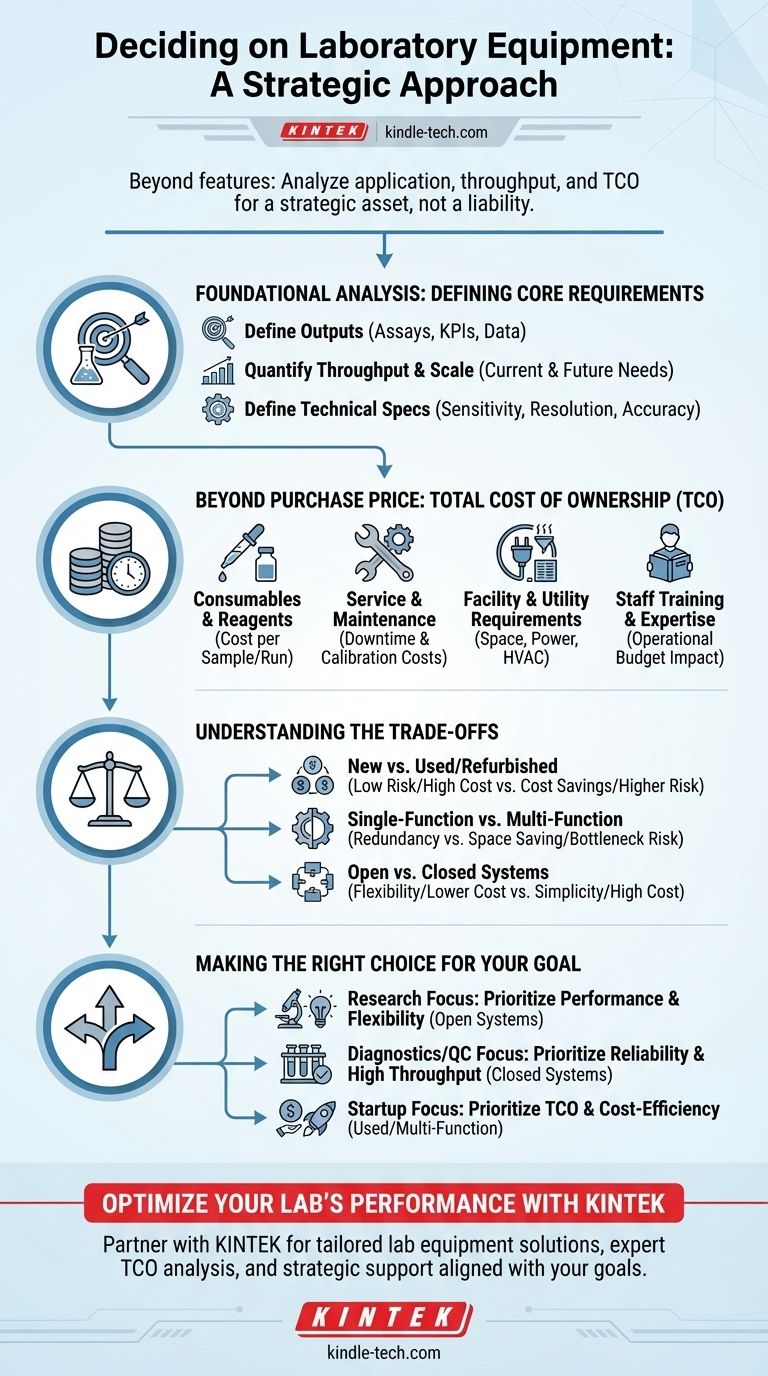

Grundlegende Analyse: Definition Ihrer Kernanforderungen

Bevor Sie auch nur eine einzige Produktbroschüre ansehen, müssen Sie zunächst das Problem definieren, das Sie lösen möchten. Die Ausrüstung ist das Mittel zum Zweck, nicht der Zweck selbst.

Beginnen Sie mit dem Endziel: Was sind Ihre Ergebnisse?

Der wichtigste erste Schritt besteht darin, die Daten, Proben oder Produkte, die Sie generieren müssen, genau zu definieren. Welche spezifischen Assays werden Sie durchführen? Was sind die wichtigsten Leistungsindikatoren für ein erfolgreiches Ergebnis?

Diese Klarheit über das Endergebnis bestimmt die grundlegende Technologie, die Sie benötigen, und filtert von Anfang an eine große Anzahl irrelevanter Optionen heraus.

Quantifizieren Sie Ihren Durchsatz und Ihre Skalierung

Sie müssen Ihre betrieblichen Anforderungen quantifizieren. Wird dieses Instrument für einige wenige wertvolle Proben pro Woche verwendet oder muss es Hunderte von Proben pro Tag verarbeiten?

Berücksichtigen Sie nicht nur Ihren aktuellen Bedarf, sondern auch Ihr prognostiziertes Wachstum für die nächsten 3-5 Jahre. Ein System, das für Ihre Startphase perfekt ist, kann ein Jahr später zu einem lähmenden Engpass werden.

Definieren Sie Ihre technischen Spezifikationen

Nachdem Sie Ihre Ergebnisse und den Umfang definiert haben, können Sie nun die erforderlichen technischen Spezifikationen auflisten. Dazu gehören Parameter wie Empfindlichkeit, Auflösung, dynamischer Bereich, Genauigkeit der Temperaturregelung und Probenvolumenkapazität.

Seien Sie spezifisch und realistisch. Anforderungen an Spezifikationen, die Sie nicht wirklich benötigen, erhöhen die Kosten dramatisch und schränken Ihre Optionen ein.

Jenseits des Kaufpreises: Die Gesamtkosten des Besitzes (TCO)

Der angezeigte Preis ist oft nur der kleinste Teil der wahren Kosten eines Instruments. Eine gründliche TCO-Analyse trennt eine gute Kaufentscheidung von einer katastrophalen.

Verbrauchsmaterialien und Reagenzien

Viele Geschäftsmodelle basieren auf dem „Rasierer und Klingen“-Prinzip. Das Instrument selbst mag erschwinglich sein, zwingt Sie aber dazu, teure, proprietäre Verbrauchsmaterialien oder Reagenzien zu kaufen.

Berechnen Sie immer die Kosten pro Probe oder Kosten pro Lauf, einschließlich aller notwendigen Verbrauchsmaterialien. Dieser Wert ist eine weitaus genauere finanzielle Kennzahl als der ursprüngliche Kaufpreis.

Service, Wartung und Kalibrierung

Wie hoch sind die Kosten für einen jährlichen Wartungsvertrag? Wie hoch ist die garantierte Reaktionszeit des Anbieters, wenn das Gerät ausfällt? Ausfallzeiten sind versteckte Kosten, die ins Gewicht fallen.

Berücksichtigen Sie außerdem die Häufigkeit und die Kosten der erforderlichen Kalibrierung. Ein zuverlässiges, wartungsarmes Instrument kann einen höheren Anfangspreis über seine Lebensdauer leicht rechtfertigen.

Anlagen- und Versorgungsanforderungen

Ein Instrument existiert nicht im luftleeren Raum. Benötigt es einen speziellen Stromanschluss mit hoher Ampere-Zahl, spezielle Gasleitungen, Sanitärinstallationen oder erhebliche Aufrüstungen der Belüftung (HLK)?

Diese Anlagenkosten können erheblich sein und müssen in das Gesamtprojektbudget einbezogen werden. Stellen Sie sicher, dass Sie über den physischen Raum und die Infrastruktur verfügen, um die Ausrüstung zu unterstützen.

Schulung und Fachwissen des Personals

Wer wird die Geräte bedienen und warten? Komplexe Instrumente erfordern möglicherweise die Einstellung von spezialisiertem Personal oder Investitionen in umfangreiche und oft kostspielige Mitarbeiterschulungen. Die Benutzerfreundlichkeit und der Automatisierungsgrad können direkte Auswirkungen auf Ihr Betriebskostenbudget haben.

Die Abwägungen verstehen

Jede Geräteeinwahl beinhaltet das Abwägen konkurrierender Prioritäten. Sich dieser Kompromisse bewusst zu sein, ist entscheidend für eine fundierte Entscheidung.

Neue vs. gebrauchte/generalüberholte Geräte

Neue Geräte bieten eine vollständige Garantie, die neueste Technologie und dedizierten Support durch den Anbieter. Dies ist die Option mit dem geringsten Risiko, aber den höchsten Kosten.

Gebrauchte oder generalüberholte Geräte können erhebliche Kosteneinsparungen bieten. Sie bergen jedoch ein höheres Ausfallrisiko, möglicherweise mangelnden Support und entsprechen möglicherweise nicht der Leistung neuerer Modelle. Dies ist eine praktikable Option, wenn Sie über internes technisches Fachwissen für Wartung und Reparatur verfügen.

Einfunktions- vs. Multifunktionsplattformen

Ein Multifunktionsinstrument kann erheblich Platz im Labor und Anfangskapital sparen, indem es mehrere Funktionen in einem Gerät vereint.

Der Hauptnachteil ist, dass es zu einem Workflow-Engpass werden kann, da jeweils nur eine Funktion genutzt werden kann. Ein Ausfall in einem Modus kann die gesamte Plattform unbrauchbar machen. Einfunktionsgeräte nehmen zwar mehr Platz ein, bieten aber Redundanz und parallele Arbeitsabläufe.

Offene vs. geschlossene Systeme

Dies ist eine der wichtigsten strategischen Entscheidungen. Geschlossene Systeme binden Sie an einen einzigen Anbieter für alle Reagenzien und Verbrauchsmaterialien. Sie bieten Einfachheit und optimierten Support, allerdings zu hohen langfristigen Kosten und ohne jegliche Flexibilität.

Offene Systeme ermöglichen die Verwendung von Reagenzien und Verbrauchsmaterialien von Drittanbietern. Dies bietet Flexibilität und kann die Betriebskosten drastisch senken, erfordert jedoch oft mehr internes Fachwissen zur Entwicklung und Validierung von Protokollen.

Die richtige Wahl für Ihr Ziel treffen

Um Ihre Entscheidung abzuschließen, integrieren Sie Ihre Analyse in einen umsetzbaren Plan. Priorisieren Sie Ihre Bedürfnisse basierend auf dem Kernauftrag Ihres Labors.

- Wenn Ihr Hauptaugenmerk auf Spitzenforschung liegt: Priorisieren Sie Leistungsmerkmale und Systemflexibilität (offene Systeme), um neuartige Anwendungen und Entdeckungen zu ermöglichen.

- Wenn Ihr Hauptaugenmerk auf Routine-Diagnostik oder Qualitätskontrolle liegt: Priorisieren Sie Zuverlässigkeit, hohen Durchsatz, niedrige Kosten pro Probe und einen starken Servicevertrag, wodurch geschlossene Systeme möglicherweise besser geeignet sind.

- Wenn Sie ein Startup mit begrenztem Kapital sind: Bewerten Sie aggressiv die Gesamtkosten des Besitzes von gebrauchten Geräten oder Multifunktionsplattformen und planen Sie gleichzeitig sorgfältig für die Risiken potenzieller Ausfallzeiten.

Ein gut ausgestattetes Labor ist nicht eines mit den teuersten Werkzeugen, sondern eines, bei dem jedes Instrument ein bewusster und strategischer Vermögenswert ist, der auf Ihre Ziele abgestimmt ist.

Zusammenfassungstabelle:

| Wichtiger Entscheidungsfaktor | Beschreibung |

|---|---|

| Kernanforderungen | Definieren Sie Ergebnisse, Durchsatz und technische Spezifikationen, bevor Sie Geräte bewerten. |

| Gesamtkosten des Besitzes (TCO) | Berücksichtigen Sie Kosten für Verbrauchsmaterialien, Wartung, Anlagen-Upgrades und Personalschulungen. |

| Abwägungen | Balancieren Sie zwischen neu vs. gebraucht, Einfunktion vs. Multifunktion und offenen vs. geschlossenen Systemen. |

| Zielausrichtung | Priorisieren Sie Leistung für Forschung, Zuverlässigkeit für Diagnostik oder Kosteneffizienz für Startups. |

Optimieren Sie die Leistung und das Budget Ihres Labors mit der richtigen Ausrüstungsstrategie. Bei KINTEK sind wir darauf spezialisiert, hochwertige Laborgeräte und Verbrauchsmaterialien anzubieten, die auf Ihre einzigartigen Bedürfnisse zugeschnitten sind – sei es bei der Weiterentwicklung der Forschung, der Skalierung der Diagnostik oder der Gründung eines Startups. Lassen Sie sich von unseren Experten dabei helfen, die TCO zu bewerten, kostspielige Fallstricke zu vermeiden und Instrumente auszuwählen, die Ihren Zielen entsprechen. Kontaktieren Sie uns noch heute, um Ihre Laboranforderungen zu besprechen und herauszufinden, wie KINTEK Ihren Erfolg unterstützen kann!

Visuelle Anleitung

Ähnliche Produkte

- Schräges Plasma-unterstütztes chemisches Gasphasenabscheidungs-PECVD-Röhrenofen-Gerät

- 915MHz MPCVD Diamantmaschine Mikrowellen-Plasma-Chemische Gasphasenabscheidung Systemreaktor

- RF PECVD System Hochfrequenz-Plasma-unterstützte chemische Gasphasenabscheidung RF PECVD

- HFCVD-Maschinensystemausrüstung für Ziehstein-Nanodiamantbeschichtung

- Vakuum-Heißpressmaschine für Laminierung und Heizung

Andere fragen auch

- Wie wird Energie in Biomasse umgewandelt? Die Nutzung der natürlichen Sonnenkraft für erneuerbare Energien

- Warum ist Pflanzenkohle besser als Holzkohle? Die richtige Kohlenstoffart für Ihr Ziel erschließen

- Wie trägt ein Trockenschrank mit konstanter Temperatur zu Bi2O3/GO-Dünnschichten bei? Expertenhärtung für überlegene Haftung

- Wie erkennt man, ob ein Filter richtig funktioniert? Der definitive Leitfaden zur Überprüfung der Wassersicherheit

- Wie kann Porosität reduziert werden? Maximale Materialfestigkeit und -dichte erreichen

- Welche verschiedenen Biomasse-Umwandlungstechniken gibt es? Passen Sie den Rohstoff an das Endprodukt an, um optimale Bioenergie zu erzielen

- Welchen Einfluss hat die Dichte auf das Sintern? Erzielen Sie überragende Qualität und Maßhaltigkeit

- Was sind die Vorteile der Vakuum-Pyrolyse? Maximieren Sie Ihren Bioöl-Ertrag und Ihre Qualität