Im Kern wird kryogenes Mahlen für Materialien eingesetzt, die bei Raumtemperatur schwer oder gar nicht zerkleinert werden können. Durch die Verwendung eines Kryogens wie flüssigem Stickstoff kühlt der Prozess ein Material ab, bis es extrem spröde wird. Diese Versprödung ermöglicht ein effizientes Zersplittern in feine, gleichmäßige Partikel und verhindert Probleme wie Schmelzen, Klebrigkeit oder die Zersetzung hitzeempfindlicher Komponenten.

Der Hauptzweck des kryogenen Mahlens besteht nicht einfach darin, ein Material kalt zu machen, sondern seine physikalischen Eigenschaften vorübergehend von duktil und zäh zu hart und spröde zu ändern. Diese Transformation überwindet die häufigsten Fehler des konventionellen Mahlens, wie Hitzeschäden, Werkzeugverschmutzung und inkonsistente Partikelgröße.

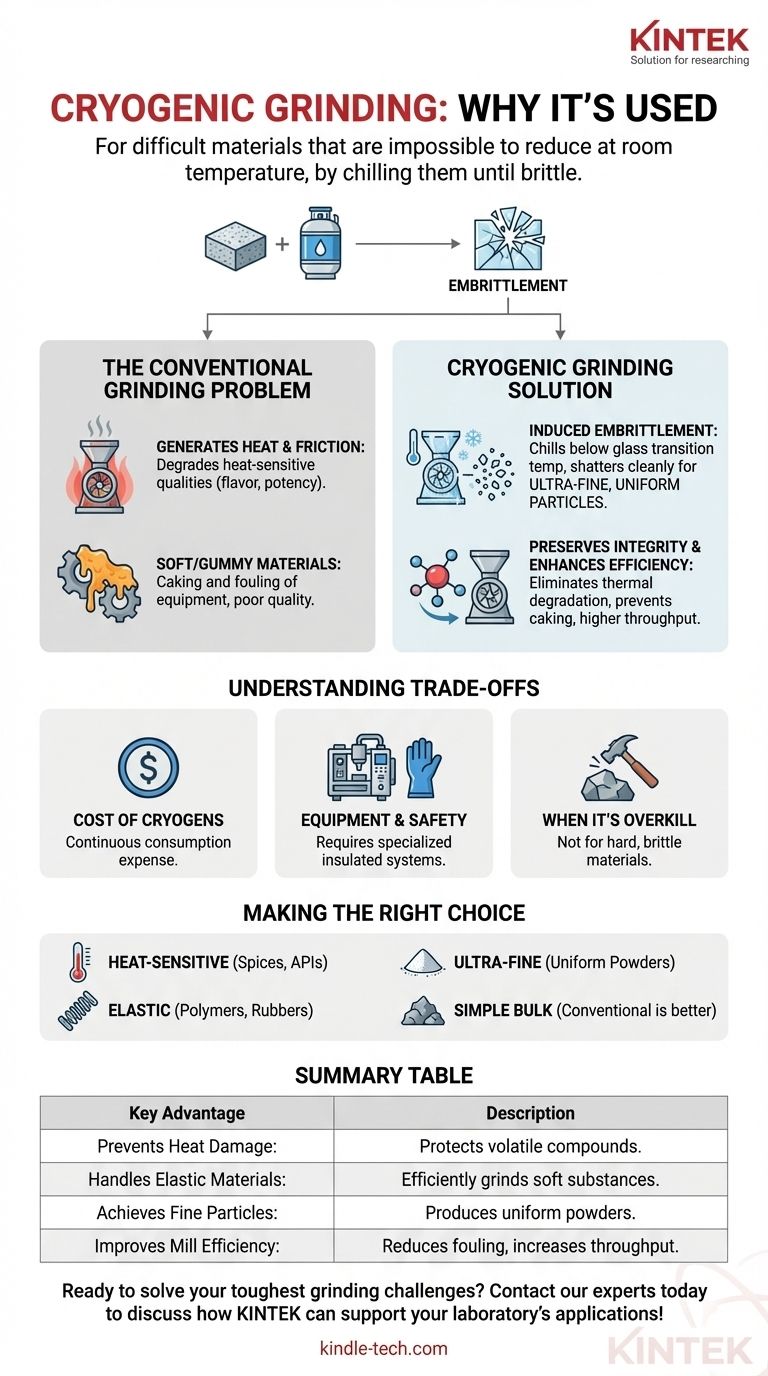

Das grundlegende Problem beim konventionellen Mahlen

Standard-Mahlverfahren basieren auf mechanischer Kraft – Schlag, Scherung oder Kompression – um Materialien zu zerkleinern. Obwohl dies für viele Substanzen effektiv ist, erzeugt dieser Prozess erhebliche Reibung und Wärme.

Wärmeerzeugung und ihre Folgen

Die intensive Energie des Mahlens wird größtenteils in Wärme umgewandelt. Bei hitzeempfindlichen Materialien wie Gewürzen, Pharmazeutika oder bestimmten Polymeren kann dies die Eigenschaften, die Sie bewahren möchten, wie Geschmack, Aroma oder chemische Wirksamkeit, beeinträchtigen oder zerstören.

Die Herausforderung weicher oder klebriger Materialien

Viele Materialien, insbesondere Kunststoffe, Elastomere und Wachse, lassen sich bei Umgebungstemperaturen nicht gut mahlen. Anstatt zu zersplittern, werden sie unter der Belastung der Mühle weich, klebrig oder elastisch. Dies führt zu Verklumpungen und Verunreinigungen der Ausrüstung, reduziertem Durchsatz und schlechter Partikelqualität.

Wie kryogenes Mahlen das Problem löst

Kryogenes Mahlen begegnet den Einschränkungen von Wärme und Duktilität direkt, indem es extreme Kälte in den Prozess einführt und so das Verhalten des Materials grundlegend verändert.

Das Prinzip der Versprödung

Das Abkühlen eines Materials unter seine Glasübergangstemperatur führt dazu, dass es seine duktilen Eigenschaften verliert und spröde und glasartig wird. Wenn die Mahlkraft angewendet wird, zersplittert das versprödete Material sauber und sofort. Dies ist der Schlüssel zur Erzielung ultrafeiner und hochgleichmäßiger Partikel.

Erhaltung der Produktintegrität

Da das gesamte System mit einem inerten Kryogen wie flüssigem Stickstoff geflutet wird, wird Wärme sofort absorbiert. Dies eliminiert thermische Zersetzung und schützt die Qualität hitzelabiler Komponenten. Es verhindert auch Oxidation durch Verdrängung von Sauerstoff und bewahrt so zusätzlich die Integrität des Endprodukts.

Verbesserung der Mühlen-Effizienz

Indem es verhindert, dass Materialien klebrig werden, eliminiert kryogenes Mahlen Produktverklumpungen in der Mühle. Dies führt zu deutlich höheren Produktionsraten, geringerem Energieverbrauch pro Produkteinheit und reduziertem Verschleiß der Mahlkomponenten. Der Prozess ist schneller und erfordert weniger Ausfallzeiten für die Reinigung.

Abwägungen und Überlegungen

Obwohl leistungsstark, ist kryogenes Mahlen ein spezialisierter Prozess mit spezifischen Anforderungen. Es ist keine Universallösung für alle Mahlaufgaben.

Die Kosten von Kryogenen

Die primären Betriebskosten sind der kontinuierliche Verbrauch von flüssigem Stickstoff oder einem anderen Kryogen. Diese Kosten müssen durch den Mehrwert gerechtfertigt sein, wie verbesserte Produktqualität oder die Möglichkeit, ein sonst unmögliches Material zu verarbeiten.

Ausrüstung und Sicherheitskomplexität

Kryogene Systeme erfordern isolierte Maschinen, spezielle Handhabungsgeräte und strenge Sicherheitsprotokolle für den Umgang mit extrem kalten Substanzen. Die anfänglichen Investitionskosten und die betriebliche Komplexität sind höher als bei konventionellen Mahlanlagen.

Wann es übertrieben ist

Für harte, spröde Materialien, die sich bei Raumtemperatur leicht mahlen lassen (z. B. Mineralien, Salze oder Keramiken), bietet kryogenes Mahlen keinen signifikanten Vorteil und würde nur unnötige Kosten und Komplexität verursachen.

Die richtige Wahl für Ihre Anwendung treffen

Die Wahl der richtigen Mahlmethode hängt vollständig von den Eigenschaften Ihres Materials und Ihren Endproduktzielen ab.

- Wenn Ihr Hauptaugenmerk auf der Erhaltung hitzeempfindlicher Eigenschaften liegt: Kryogenes Mahlen ist unerlässlich, um flüchtige Verbindungen in Gewürzen, Lebensmitteln und aktiven pharmazeutischen Wirkstoffen (APIs) zu schützen.

- Wenn Ihr Hauptaugenmerk auf der Verarbeitung weicher oder elastischer Materialien liegt: Kryogenes Mahlen ist die überlegene Methode für Polymere, Kautschuke, Wachse und Klebstoffe, die sonst schmelzen oder Geräte verunreinigen würden.

- Wenn Ihr Hauptaugenmerk auf der Erzielung ultrafeiner, gleichmäßiger Pulver liegt: Der Versprödungsprozess ermöglicht ein Maß an Partikelgrößenkontrolle und Konsistenz, das mit konventionellen Methoden oft unerreichbar ist.

- Wenn Ihr Hauptaugenmerk auf der kostengünstigen Mengenreduzierung einfacher Materialien liegt: Konventionelles Mahlen bleibt die wirtschaftlichste und unkomplizierteste Wahl für Materialien, die nicht hitzeempfindlich oder duktil sind.

Durch die grundlegende Veränderung des physikalischen Zustands eines Materials zum Zweck der Größenreduzierung erschließt kryogenes Mahlen Verarbeitungsmöglichkeiten, die sonst unerreichbar wären.

Zusammenfassungstabelle:

| Hauptvorteil | Beschreibung |

|---|---|

| Verhindert Hitzeschäden | Schützt flüchtige Verbindungen in Gewürzen, Pharmazeutika und Polymeren. |

| Verarbeitet elastische Materialien | Mahlt effizient weiche, klebrige Substanzen wie Kunststoffe und Kautschuke. |

| Erzeugt feine Partikel | Produziert ultrafeine, gleichmäßige Pulver durch Materialversprödung. |

| Verbessert die Mühlen-Effizienz | Reduziert Geräteverschmutzung, erhöht den Durchsatz und senkt den Energieverbrauch. |

Bereit, Ihre schwierigsten Mahlherausforderungen zu lösen? Wenn Sie mit hitzeempfindlichen Gewürzen, Pharmazeutika, Polymeren oder anderen schwer zu mahlenden Materialien arbeiten, können die kryogenen Mahllösungen von KINTEK die Qualität Ihres Produkts bewahren und Ihre Prozesseffizienz steigern. Unser Fachwissen im Bereich Laborgeräte stellt sicher, dass Sie das richtige System für Ihre Anforderungen erhalten. Kontaktieren Sie noch heute unsere Experten, um zu besprechen, wie wir Ihre Mahlanwendungen im Labor unterstützen können!

Visuelle Anleitung

Ähnliche Produkte

- Flüssigstickstoff-Kryomühle mit Schneckenförderer

- Labor Kryomühle mit Flüssigstickstoff zum Pulverisieren von Kunststoffrohstoffen und wärmeempfindlichen Materialien

- Tieftemperatur-wassergekühlter Vibrations-Feinstzerkleinerer mit Touchscreen

- Labor-Kugelmahlanlage mit Aluminiumoxid-Zirkonoxid-Mahlbehälter und Kugeln

- Labor Hybrid Tissue Grinder

Andere fragen auch

- Was ist kryogenes Mahlen von Lebensmitteln? Der ultimative Leitfaden zur Bewahrung von Geschmack und Aroma

- Was ist Mahlen im Labor? Der Schlüssel zur präzisen Probenvorbereitung

- Wie verbessern Zerkleinerungs- und Mahlsysteme die Gasproduktion von Mikroalgen? Optimierung der Biomassevorbehandlung für höhere Ausbeuten

- Was ist der Zweck eines Pulverisierers? Entfesseln Sie das Potenzial von Materialien durch Feinvermahlung

- Wie stellen Labormühlen und Standard-Siebsysteme die Qualität des Ausgangsmaterials für die Torrefizierung sicher?